In the critical field of temperature measurement, the role of thermocouple suppliers cannot be overstated. These suppliers are the backbone of a chain that ensures industries ranging from manufacturing to aerospace maintain precise temperature control. Amidst a sea of competitors, Tempsens emerges as a distinguished leader, setting a benchmark for what excellence looks like in this domain. Let’s delve into the reasons why Tempsens distinguishes itself from other thermocouple suppliers.

Commitment to Precision

At Tempsens, precision is not just a goal; it’s a fundamental principle. Understanding the pivotal role thermocouples play in various applications, we ensure that every product surpasses industry standards for accuracy. This relentless pursuit of precision makes us a preferred choice among thermocouple suppliers, particularly in sectors where even a minor temperature discrepancy can lead to significant consequences.

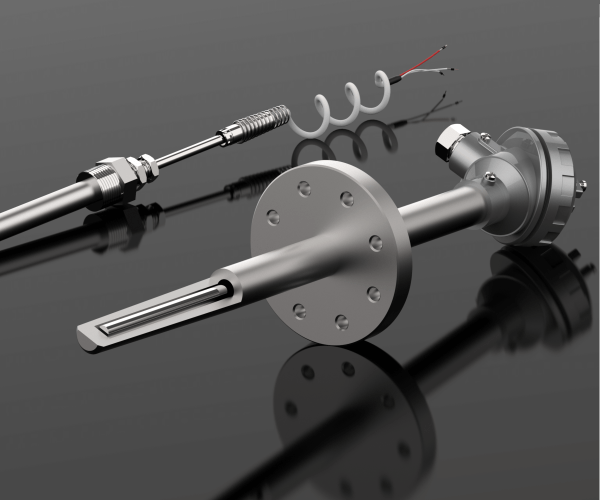

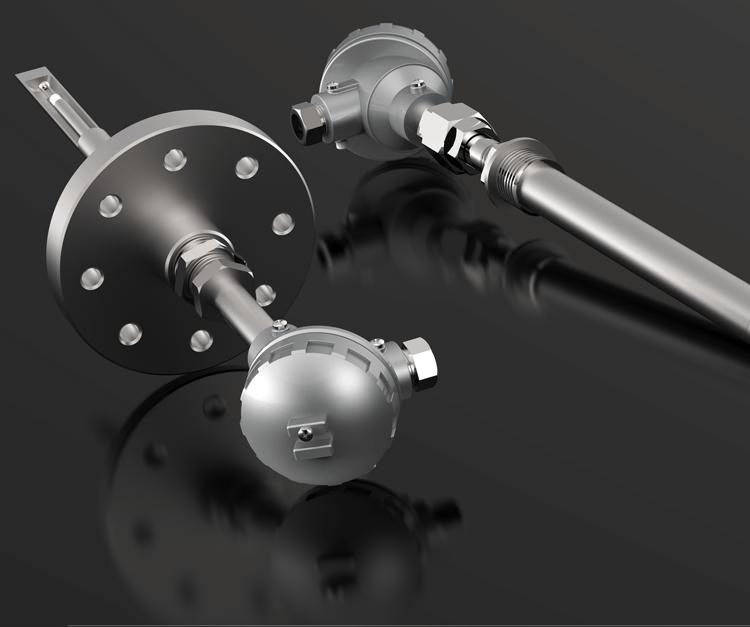

Innovation at Its Core

What truly sets us apart is its commitment to innovation. Unlike other thermocouple suppliers who may be content with the circumstances, Tempsens continuously pushes the envelope, integrating cutting-edge technologies and materials into their products. This forward-thinking approach not only enhances the functionality and longevity of their thermocouples but also positions us as a pioneer in the industry.

Customized Solutions

Recognizing that one size does not fit all, Tempsens excels in providing customized solutions that cater to the unique needs of their clients. Their willingness to adapt and design thermocouples that meet specific requirements is a testament to their customer-centric approach. This flexibility is a rare trait among thermocouple suppliers and underscores our dedication to client satisfaction.

Exceptional Customer Service

Tempsens’s commitment to excellence extends beyond its products. Their customer service is exemplary, offering support and guidance that is as reliable as their thermocouples. This exceptional after-sales support ensures that clients not only receive a product that meets their needs but also the knowledge and assistance to maximize its utility.

Global Reach, Ethical Practices

Tempsens is not just a leader locally but has established itself as a reputable name globally. Their ethical practices, coupled with a commitment to sustainability, resonate with businesses worldwide, making them a preferred partner among international clients.

In conclusion, our distinction as a leader among thermocouple suppliers is a result of its unwavering commitment to precision, innovation, customization, customer service, and ethical practices. These pillars form the foundation of our success, setting a high standard for others in the industry and ensuring that their clients receive nothing but the best.