When it comes to measuring temperature, not all thermometers are created equal. For venturing into the fiery depths of industrial furnaces or the bone-chilling cold of cryogenic chambers, you need a tool built for the extremes. This is where thermocouple thermometers come in.

Built for Tough Conditions

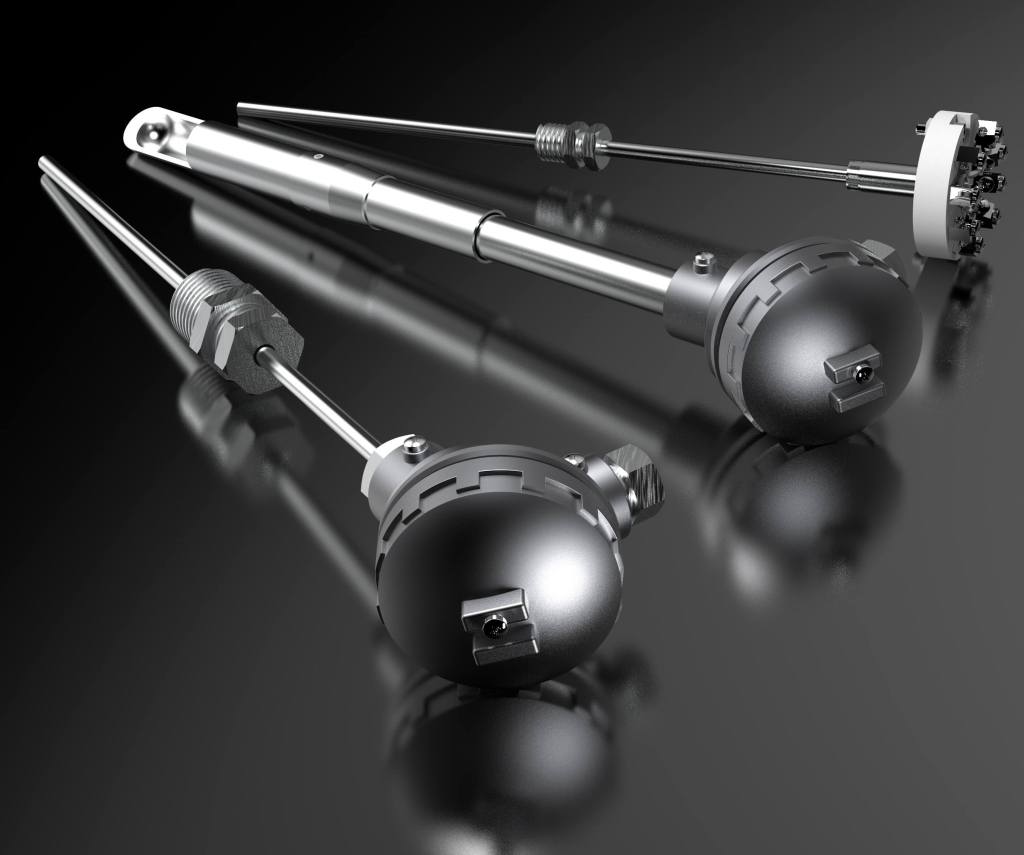

Thermocouple thermometers are robust temperature sensors that utilize the Seebeck effect. Imagine two dissimilar metals joined at a point. When one junction is exposed to a different temperature than the other, a tiny voltage is produced. This voltage is directly related to the temperature difference, allowing for accurate measurement.

The beauty of thermocouples lies in their simplicity and resilience. Unlike other thermometers that rely on complex mechanisms or exotic materials, thermocouples are essentially two wires. This makes them ideal for extreme environments:

- High Temperatures: Certain thermocouple thermometer types, like Platinum-Rhodium (Type R), can withstand temperatures exceeding 2,000°C (3,632°F) – perfect for monitoring furnaces, kilns, and reactors.

- Low Temperatures: Thermocouples like Type K (Chromel-Alumel) can dip down to cryogenic temperatures near -200°C (-328°F), making them valuable for research labs and industrial freezers.

- Harsh Environments: The all-metal construction of thermocouples makes them resistant to shock, vibration, and even some corrosive elements.

Beyond the Basics

While inherently tough, using thermocouples in extreme environments requires some additional considerations:

- Sheathing: The thermocouple wires themselves are often quite thin and delicate. To protect them in harsh environments, they are encased in a sheath made from a suitable material like metal or ceramic. Sheath selection depends on factors like temperature range, chemical compatibility, and mechanical strength.

- Reference Junction: Remember, thermocouple thermometers measure temperature differences. To determine the actual temperature at the measuring point, you need a reference point with a stable, known temperature. This is usually achieved with a special reference junction box.

- Calibration: Like any measuring tool, thermocouple thermometers require periodic calibration to ensure accuracy. This is especially important when operating at temperature extremes.

The Right Tool for the Job

Thermocouple thermometers aren’t just for the fringes of science and industry. They are a valuable tool in various applications:

- Power Generation: Monitoring turbine exhaust temperatures in power plants.

- Metalworking: Ensuring precise temperatures during welding, forging, and heat treatment.

- Food Processing: Maintaining consistent temperatures in ovens, freezers, and sterilization chambers.

- Automotive Industry: Testing engine performance and monitoring emissions control systems.

With their versatility and durability, thermocouple thermometers are the go-to choice for taking temperature measurements to the extreme. To equip these, head online at Tempsens and get exposed to premium quality materials in the best price.

Leave a comment